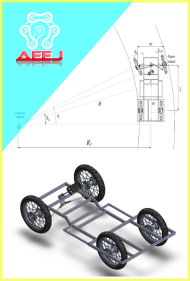

Optimizing the Knuckle Corner Design of an Urban EV8 Vehicle Category Concept to Meet Turning Radius Requirements

##plugins.themes.academic_pro.article.main##

Abstract

This research aims to achieve the smallest possible turning radius for the knuckle joint while also meeting the regulations set by the Shell Eco-Marathon (SEM) committee regarding the design angles and lengths. Calculations and testing are conducted using simulation methods to obtain suitable angles and lengths for the knuckle. This simulation method involves a series of analyses to obtain data such as static turning radius diagrams, followed by an analysis using the camber calculation formula. The shape, angle, length, and design of the knuckle are considered with regard to driving safety factors. The findings of this study indicate that for a six-meter turning radius, the outer wheel requires a steering angle of δ_0=10.868°, and the inner wheel requires a steering angle of δ_i=77.397°. After improvements, for a 5.5-meter turning radius, the outer wheel requires a steering angle of δ_0=15.960°, and the inner wheel requires a steering angle of δ_i=71.321°. It can be concluded that this design can optimize the performance of the knuckle steering system.

##plugins.themes.academic_pro.article.details##

This work is licensed under a Creative Commons Attribution 4.0 International License.

References

[2] Rosero, F., Fonseca, N., López, J. M., & Casanova, J. (2021). Effects of passenger load, road grade, and congestion level on real-world fuel consumption and emissions from compressed natural gas and diesel urban buses. Applied Energy, 282, 116195.

[3] SHELL ECO-MARATHON.” [Online]. Available: www.makethefuture.shell.Shell Eco-Marathon Asia and middle east 2022

[4] Mat MH, Ghani AR. Desain dan analisis sasis mobil “eco”. Proses Eng. 2012;41:1756–60. https://doi.org/10.1016/j.proeng.2012

[5] Airale A, Carello M, Scattina A. Serat karbon monocoque untuk prototipe hidrogen untuk tantangan konsumsi rendah. Mate rialwiss Werkstofftech. 2011;42(5):386–92. https://doi.org/10. 1002/mawe.201100793 [7] Ary AK, Prabowo AR, Imaduddin F.

[6] Fajar, D. I. (2015). Analisa Sistem Kemudi Mobil Listrik Brajawahana ITS Terhadap Kondisi Ackerman. Teknik Mesin, Fakultas Teknologi Industri, Institut Teknologi Sepuluh Novenmber.

[7] Babu, B., Prabhu, M., Dharmaraj, P., & Sampath, R. (2014). Stress analysis on steering knuckle of the automobile steering system. International journal of Research in Engineering and Technology, 3(3), 363-366.

[8] Bin Zheng (2022). Shell Eco-marathon Global Technical Director. Shell eco marathon official Rules

[9] FAHMIZAL, F., MURTI, B. B., PRATAMA, D. B., & MAYUB, A. (2018). Kendali Logika Fuzzy pada Car Like Mobile Robot (CLMR) Penjejak Garis. ELKOMIKA: Jurnal Teknik Energi Elektrik, Teknik Telekomunikasi, & Teknik Elektronika, 6(3), 451.

[10] Reza N. Jazar. Vehicle Dynamics: Theory and Application. Springer: 2007

[11] Smith, J. (2018). The Importance of Ackermann Geometry in Vehicle Steering. Journal of Automotive Engineering, 25(2), 45-58.

[12] Johnson, A., & Anderson, B. (2020). Simulation Analysis of Steering Angles in Solidworks 2020. International Journal of Vehicle Dynamics, 12(3), 87-102.

[13] Brown, C., & Williams, E. (2019). Effects of Slip Angles on Vehicle Turning Conditions. Proceedings of the International Conference on Vehicle Dynamics and Control, 125-140.

[14] Li, H., & Chen, G. (2017). Optimization of Steering Angles for Improved Vehicle Performance. Journal of Automobile Engineering, 33(1), 75-88.

[15] Harris, R., & Johnson, M. (2022). The Influence of Steering Geometry on Vehicle Handling. International Journal of Automotive Engineering, 29(1), 65-78.